-

Client

A large international media corporation

-

Business need

Ensuring clients' Data Centres running efficiently, reducing costs and minimising down-time

The Challenge

Our client, a large international media corporation, was upgrading one of its older data centres to improve efficiency and reduce running and maintenance costs. The data centre was designed to use mixed flow cooling, but the client wanted to move to a Cold Aisle Containment strategy; this would make use of the existing underfloor void to supply the cold air from the Computer Room Air-Conditioning (CRAC) units to the server racks, through perforated tiles. However, the floor void was not designed to be used in this way, and contained a number of blockages from steps, supports and underfloor cabling. As a result, the down-selected CRAC suppliers were unable to confirm if their units would be able to supply the flow required to cool the servers.

Due to the CAPEX required for the upgrade, our client needed confidence that the CRAC units being proposed by its suppliers would be able to supply the required cooling flow. In addition, to reduce the time and cost of the upgrade, our client wanted to understand if it could make use of the existing duct work in the ceiling void to return the hot air to the CRACs.

Data centre cooling

Video: Contours of temperature and velocity vectors throughout the proposed data centre.

Our solution

Our highly skilled team of fluid dynamics and heat transfer experts used Computational Fluid Dynamics (CFD) simulations to determine the External Static Pressure (ESP) required by the CRAC units to overcome the blockages in the underfloor void. Computational Fluid Dynamics is an advanced modelling technique that is able to predict the flow velocities, pressure losses and temperatures within the data centre. As a result, our team was able to determine which CRAC units would be able to provide the necessary cooling, allowing our client to purchase their equipment with confidence, knowing that it would be able to perform as required.

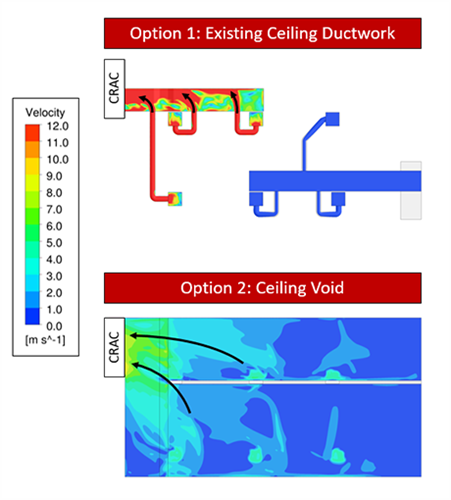

We also used our CFD simulations to investigate whether the existing duct work could be used to return the hot air to the CRAC units. We found that doing so would place a substantial ESP demand on the CRAC units, preventing them from providing the required cooling flow. Consequently, our client was able to plan upfront for the removal of the existing ceiling duct work as part of the re-fit, rather than having to undertake costly and time consuming post-installation modifications to the system.